Caring for Stainless Steel Countertops in Laboratories

Cleanrooms and pharmaceutical labs are critical environments where the handling, testing, and manufacturing of sensitive materials take place. These facilities must adhere to strict cleanliness and sanitation standards to ensure product quality, accuracy, and safety.

One crucial aspect of maintaining these standards is the careful selection of surface materials for lab furniture. Among the various options available, stainless steel has emerged as one of the most popular choices due to its inherent cleanliness and performance.

Importance of Stainless Steel in Cleanrooms

Cleanrooms cater to diverse industries, such as semiconductor manufacturing and OLED display production, where researchers and technicians work with a range of vulnerable materials.

Similarly, pharmaceutical labs handle various chemicals, substances, and drugs, necessitating a controlled environment to ensure safety and accurate results. The surface materials used in these settings must align with the unique requirements and pace of the facility.

The Food and Drug Administration (FDA) has established rigorous standards and requirements for pharmaceutical labs and similar facilities to safeguard consumers and ensure safe working conditions.

The FDA has been involved in setting sanitary standards for manufacturers since the early 20th century and has progressively assumed more responsibility for overseeing the development of food and pharmaceutical products.

Qualities of Stainless Steel

Good Manufacturing Practices (GMP) is a set of guidelines developed by the FDA to ensure manufacturers maintain consistent standards and quality. For cleanrooms and pharmaceutical labs, stainless steel is often the preferred choice of surface material, as indicated by the specific instructions provided by GMP protocols.

Stainless steel possesses several key qualities that make it ideal for cleanroom equipment and furniture. Apart from being inherently clean, stainless steel exhibits exceptional resistance to corrosion, making it durable against exposure to moisture and corrosive substances.

Stainless steel is a non-porous surface that is easy to clean, preventing the accumulation of particulate matter, dirt, and grime, thereby minimizing the risk of cross-contamination. Stainless steel also boasts high tensile strength, longevity, and an enduring aesthetic appeal. It can withstand high temperatures of up to nearly 1,600 degrees Fahrenheit without warping or pitting.

Stainless Steel Countertop Grades

Stainless steel countertops have gained popularity in laboratories due to their key features of being durable and aesthetically appealing. When selecting the perfect stainless-steel material for your lab countertops, understanding the differences between the 304 and 316 grades is crucial.

Both 304 and 316 stainless steel offer excellent corrosion resistance, making them ideal laboratory countertop materials. However, 316 stainless steel exhibits superior resistance to corrosive agents like salts, acids, and chlorides.

Interested in delving deeper into the differences between the two prominent stainless steel grades? Read our past blog on the topic! By walking through the unique characteristics, we aim to assist you in making an informed decision on the most appropriate grade of stainless steel countertops for your specific laboratory application.

Cleaning and Maintenance of Stainless Steel Surfaces

Cleaning stainless steel in a cleanroom environment is crucial to prevent cross-contamination. Staff working in these facilities devote significant time to maintaining cleanliness, necessitating knowledge of proper cleaning methods for different surface materials and equipment. Stainless steel has specific cleaning requirements but is relatively easy to keep clean, streamlining laboratory operations.

Cleaning stainless steel enhances its resistance to corrosion and damage. Unlike other materials, stainless steel does not wear down or become dull from vigorous cleaning. Besides preserving strength and durability, regular cleaning of furniture and equipment helps reduce cross-contamination, prevent unsightly messes, and maintain the aesthetic appeal of surfaces.

For routine cleaning of stainless steel, warm water and a soft cloth or non-abrasive sponge are usually sufficient to remove normal spills and small stains.

If necessary, a mild detergent or soap can be used. In cases of tougher messes such as caked-on stains, grease, oil, and fingerprints, solvents like non-sterile or sterile 70% isopropyl alcohol are effective disinfectants for stainless steel. After cleaning with solvents, surfaces should be rinsed with warm water and dried with a lint-free cloth to prevent corrosive materials from compromising the protective film layer on stainless steel.

While stainless steel is highly resistant to heat, corrosion, and general damage, it is not impervious to harm. Certain chemicals, products, and techniques should be avoided to prevent damage to stainless steel.

Chlorine and bleach can deteriorate the protective surface layer and lead to pitting and surface disturbances. Abrasive cleaners and cleaning products like steel wool should be avoided to prevent scratching. Allowing dirt and grime to accumulate for prolonged periods can also damage the protective layer, but passivation can help reverse the effects.

Passivation & Electropolishing

When stainless steel is freshly made, it forms a protective oxide layer on its surface upon exposure to air. This layer contributes to stainless steel’s corrosion resistance and gradually rebuilds over time. However, the presence of dirt or oils on the surface inhibits the formation of this protective layer.

Therefore, regular cleaning is essential for stainless steel to produce its natural protective oxide layer effectively. Passivation is a process used to repair stainless steel surfaces that have lost their ability to spontaneously produce a protective passive film.

It involves applying a chemical solvent like a nitric acid solution to remove iron/iron compounds from the surface, enhancing the material’s corrosion resistance. Passivation is also used as a preventative measure to maintain stainless steel quality and prevent corrosion and rusting.

Electropolishing is another process used to resurface stainless steel. It removes microscopic pits and spikes from the surface, creating a smooth and poreless finish. This mirror-like surface prevents the buildup of bacteria, dirt, oils, and chemical residue.

Selecting Quality Stainless Steel Laboratory Countertops

When selecting stainless steel equipment or furniture, it is essential to choose items from reputable companies that offer quality guarantees. At ChemTops, a wide range of NSF-tested stainless steel products, manufactured in the USA, are available.

We specialize in custom-designing lab countertops to meet specific facility needs. Stainless steel laboratory countertops are of the highest quality, designed to withstand regular contamination, moisture, and heat commonly found in laboratory environments.

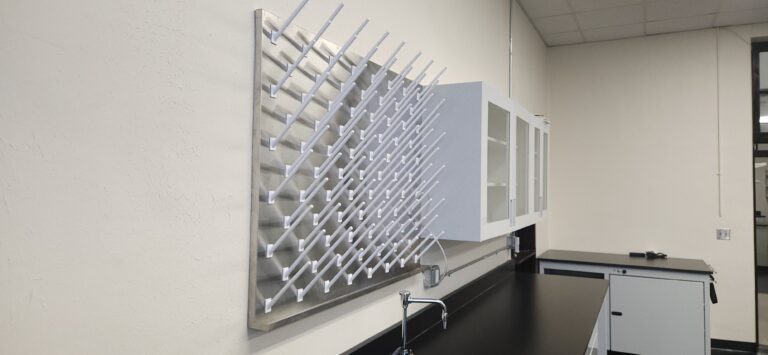

In addition to countertops, ChemTops offers other essential laboratory equipment, such as stainless steel laboratory drying racks and stainless steel sinks, designed to reduce the buildup of contaminants.

Enhance Your Cleanroom with ChemTops' Premium Stainless Steel Furniture!

Maintaining the cleanliness and integrity of a cleanroom or pharmaceutical lab is of paramount importance. Choosing the right surface materials, such as stainless steel, and following proper cleaning and maintenance procedures are crucial steps in ensuring a safe and effective working environment.

If you require stainless steel countertops for your laboratory or would like to discuss any other countertop materials, contact ChemTops at (866) 612-74312 to speak with a representative.